Serviços Personalizados

Journal

Artigo

Indicadores

-

Citado por SciELO

Citado por SciELO -

Acessos

Acessos

Links relacionados

-

Similares em

SciELO

Similares em

SciELO

Compartilhar

Revista de Ciências Agrárias

versão impressa ISSN 0871-018X

Rev. de Ciências Agrárias vol.39 no.3 Lisboa set. 2016

https://doi.org/10.19084/RCA15087

ARTIGO

Biogas production by the anaerobic digestion of whey

Produção de biogás por digestão anaeróbia do soro de leite

Jhonatas Antonelli1*, Cleber Antonio Lindino2, Júlio Cesar Rodrigues de Azevedo3, Samuel Nelson Melegari de Souza2, Paulo André Cremonez2 and Eduardo Rossi2

1 Federal University of Paraná, Paraná, Brazil. *E-mail: jonatas-a@hotmail.com

2 University of West Paraná, Paraná, Brazil;

3 Federal Technological University of Paraná, Paraná, Brazil.

ABSTRACT

Digestion is an attractive alternative in the treatment of waste generated in the agricultural industry, as it treats waste and also produces biogas that can be used in power generation, resulting in both environmental and economic benefits. This study presents the results of anaerobic digestion of cheese whey using swine wastewater as inoculum. Digestion was performed using sequencing batch bioreactors with a total volume of 2.350 mL. In order to evaluate digester efficiency, biogas was collected in a gas meter. Methane concentration in the biogas was determined using a biogas analysis kit, by AlfaKit®. The project was carried out using two different temperatures, which were 32ºC and 26ºC, that resulted in the production of 270 and 171 L (kg-sv)-1 of biogas, respectively and a reduction of over 40% in volatile solids in both treatments. The tests show that there is a good potential for the use of whey in the production of biogas and its further conversion into energy.

Keywords: agro-industrial waste; anaerobic digestion; methane production; reduction of volatile solids; renewable energy.

RESUMO

A biodigestão é uma alternativa atraente no tratamento de alguns resíduos gerados na agroindústria, pois além de tratar o resíduo, produz o biogás que pode ser utilizado na geração de energia. Este trabalho apresenta os resultados de digestão anaeróbia de soro de queijo utilizando água residual de suinocultura como inoculo. A biodigestão foi executada em batelada utilizando biorreatores com volume total de 2.350 mL. Para avaliar a eficiência do biodigestor, o biogás produzido foi coletado em gasômetro, a concentração de metano no biogás foi determinada utilizando kit de Análise de Biogás, da AlfaKit®. O projeto foi realizado utilizando duas temperaturas diferentes, sendo elas 32 e 26 ºC resultou na produção de 270 e 171 L (kg-sv-1) de biogás respectivamente. Os testes realizados mostram que existe um bom potencial para o uso de soro de queijo para a produção de biogás e posterior conversão deste em energia.

Palavras chave: biodigestão, energia renovável, produção de metano, redução de sólidos voláteis, resíduo agroindustrial.

Introduction

Anaerobic digestion is a technique that has been widely used in various fields in order to perform the treatment of wastes with high organic load. In Brazil, due to the implementation of new environmental rules, the use of digesters has become very common in the treatment of agro-industrial residues. The deployment of this technology for wastewater treatment can bring various environmental and economic benefits, including the production of energy in the form of electricity and heat (Amon et al., 2007).

In the conversion of organic matter into biogas under conditions of absence of oxygen, inorganic electron acceptors such as ions NO3-, SO2, and CO2 are used. The production of methane occurs in environments in which oxygen, nitrate and sulfate are not readily available, then CO2 is used as an electron acceptor (Cáceres et al., 2012).

Anaerobic digestion usually occurs in two stages, the first of which is formed by facultative and anaerobic bacteria that aim to convert complex organic compounds into simpler ones, such as volatile acids. The second stage is formed by strictly anaerobic bacteria, which convert the products formed by the first group into methane and carbon dioxide (Rojas et al., 2011; Cáceres et al., 2012).

The process of anaerobic digestion can be divided into four main stages, namely: hydrolysis, which is the breakdown of complex particulate materials into simpler dissolved materials; acidogenesis: in this phase the soluble products from the hydrolysis stage are metabolized within the cells of fermentative bacteria. The acetogenesis bacteria are responsible for the oxidation of products generated in the acidogenic stage in substrate that is suitable for the methanogenic; methanogenesis: uses the compounds formed in the previous stage in the production of methane and carbon dioxide (Rojas et al., 2011; Cáceres et al., 2012).

Currently in Brazil, most of the biogas used in energy production use livestock and agricultural wastes as raw material. Biogas produced in the digesters can be used in various activities such as home heating, heating of animals, production of electricity, lighting or sale of purified biogas as a vehicle fuel (Teghammar et al., 2014).

The use of biogas produced by the anaerobic digestion of wastewater in Brazilian agribusiness is a practice that has been increasingly used in order to generate electricity; this practice brings both environmental and economic benefits. In Europe, the use of anaerobic digestion of waste in biogas production is a practice widely used, mainly for the production of thermal energy, and the predominant substrates used are manure, grass or corn silage and often organic industrial waste (Hjort-Gregersen et al., 2011).

The industrialization of milk is growing throughout the world due to the increased consumption of milk and its derivatives. According to EMBRAPA (2010), milk production is a major agribusiness and occupies the 4th place among the agricultural commodities produced in Brazil. According to the USDA (2014), Brazil is the 5th largest milk producer in the world with 32.380 million tons, and the third in cheese production (722,000 tons). Europe is the largest producer of milk in the world with 139.100 million tons and the largest producer of cheese with 9.175 million tons in 2013.

The dairy industry is a major producer of various products such as yogurt, milk and cheese, accounting for a high potential of organic pollution. Whey is the main by-product of the production of cheese, which contains high amount of organic material; this residue is traditionally used as a supplement or animal feed, or discarded as industrial waste (Cheng, 2007).

The volume of effluent produced in the cheese manufacturing industry has increased greatly in recent years because there has been a considerable increase in the production and consumption of this product. It is estimated that the industry uses 10 kg of milk to manufacture 1 kg of cheese, resulting in 9 kg of cheese whey (Prazeres et al., 2012).

Cheese whey characterization

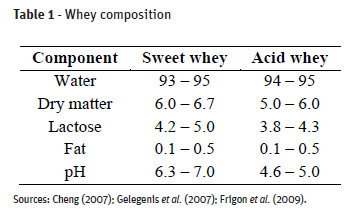

Cheese whey is a by-product of cheese production. According to Ergüder et al. (2001), it is rich in protein and lactose with high organic matter content (Table 1). It shows high biodegradability and relatively high alkalinity. Cheese whey accounts for 70% to 75% of the lactose present in the milk and 10% to 15% of soluble proteins, what results in chemical oxygen demand (COD) between 50 and 70 g L-1 (Frigon et al., 2009).

The precipitation of casein leads to the formation of two types of whey: acid whey (pH = 5), which is obtained after fermentation or addition of organic or mineral acids; and sweet whey (pH = 6 to 7), which is obtained by the addition of proteolytic enzymes such as chymosin (Panesar et al., 2007).

The concentration of lactose and fat is considered the main responsible for the chemical and biochemical oxygen demand of cheese whey. With their high concentration of organic matter, these effluents can create serious problems in the organic load of municipal sewage treatment systems (Janczukowicz et al., 2008).

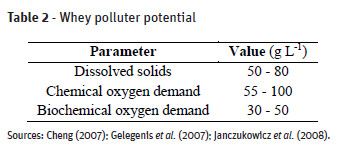

As shown in Table 2, whey may be considered as a potentially high pollutant to the environment. According to Gelegenis et al. (2007), its biochemical oxygen demand is very high, typically between 30 and 50g L-1 whereas its chemical oxygen demand is between 60 and 100 g L-1.

The objective of this study was to evaluate the potential of biogas production by means of whey digestion at different temperatures, using swine wastewater as inoculum.

Materials and methods

For project design reactors, firstly the reactors were made using polyvinyl chloride pipes. The second stage was characterized by obtaining the feed material and inoculum, which have gone through a treatment to correct the pH. Then the material was conditioned in the reactors, which were maintained at a constant temperature. The measurements, collection and analysis of the produced biogas were constantly performed in order to obtain the volume and quality of the biogas.

Experimental design

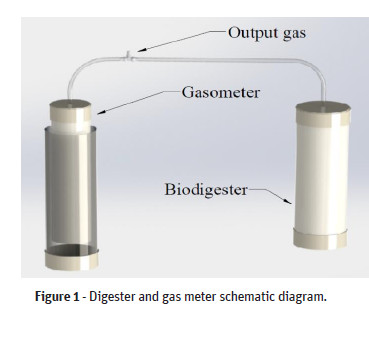

The assemblage of the gas meter and reactor was carried out according to Figure 1. The anaerobic sequencing batch reactors used were made of polyvinyl chloride (PVC) tubes with diameter of 100 mm, length of 300 mm and volume of 2.350 mL. The gas meter consisted of a PVC tube measuring 75 mm diameter by 300 mm length, which was inserted in a PVC tube of 100 mm diameter by 300 mm length filled with water, in order to form a water seal, thus avoiding loss of biogas. Biogas was removed through a relief valve inserted in the hose connecting the digester to the gas meter.

Material

Cheese whey used in this study was collected in 30 L containers from a small dairy farm located in the city of Cascavel, Paraná, Brazil. Collection was performed immediately after whey exiting the process, at a temperature of 53ºC. The material collected presented pH of 6.53 and total solids of 59.22g L-1. These values are similar to those found by Comino et al. (2012) and Kavacik et al. (2010). The material was inserted in the digester on the same day of collection.

Swine wastewater used as inoculum was collected in a 20 L container from the exit pipe of a digester situated at a rural property located in Palotina, Paraná.

Waste treatment

Whey has the capacity of fast acidification, thus, to avoid reactor collapse, it is necessary to neutralize it and add a buffer solution to it (Comino et al., 2012). An aqueous sodium hydroxide (NaOH) solution in the concentration 10 mol L-1 was prepared for the cheese whey neutralization in this study. Whey was corrected to a pH of 7.45. An aqueous sodium hydrogen carbonate (NaHCO3) solution at 1 mol L-1 was used as buffer solution.

Cheese whey digestion

The cheese whey digestion process was carried out at the laboratory of biofuel catalysis and production (LABCATPROBIO), at the State University of West Paraná, located in western Paraná, Brazil. The process had the duration of nine days.

In the digestion process, 80% of the total volume of the reactor was used (1.880 mL), being 20% inoculum (376 mL) and 80% cheesy whey (1.504 mL). The work was performed in triplicate using two different temperatures, totaling 12 digesters. For purposes of temperature control, the laboratory was kept under refrigeration at 22ºC. In order to maintain temperature, digesters were placed into containers filled with water heated at 26ºC and 32ºC by two thermostats of 150W each.

Biogas analysis

The biogas generated was collected and then analyzed with a biogas analysis kit, by AlfaKit®, which was able to determine carbon dioxide (CO2) values due to the Orsat method adaptation, in which a basic solution reacts with CO2, making it precipitate so it can be measured. Methane gas (CH4) values (in percentage) were obtained indirectly by verifying the difference in the CO2 content in the biogas at precision of ± 5%. The same kit was used to determine ammonia (NH3) and sulphydric gas (H2S) concentrations.

Results and discussion

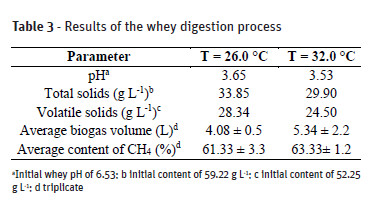

Table 3 presents the results obtained in the whey digestion process, under the conditions and quantities studied, after the digestion period.

Results show that the reductions in total solids content were 42.84% and 49.51% under temperatures of 26°C and 32°C, demonstrating a decrease in organic load and indicating an improvement in the COD/BOD of the effluent, with less environmental impact. Volatile solids reductions were 45.76% and 53.11%, respectively. Substratum acidification causes a reduction in biogas generation, what required pH control during the handling of the digester.

The volume of biogas produced is 30.9% higher at 32.0°C than at 26.0°C. Students t-test indicates that there is no statistically significant difference between methane contents and both temperatures at a 95% confidence interval.

The proportion solid material/biogas generation at 32.0ºC was 270 L (kg-sv-1). Considering 61.33% of CH4 in biogas, 168 to 174 L (kg-sv-1) of methane was produced. These results are similar to those found by Amon et al. (2007), with a CH4 methane yield of 166.3 L (kg-sv-1), and by Lehtomaki et al. (2007), with a yield that ranged from 149 to 268 L (Kg-sv-1).

At 26ºC, biogas yielded 171 L (kg-sv-1) whereas methane production varied from 99 to 110 L (kg-sv-1). These results were similar to the ones observed by Comino et al. (2012) with a CH4 yield of 108.75 L (kg-sv-1) and by Comino et al. (2010), with a yield of 119.25 L (kg-sv-1).

According to Maizonnasse et al. (2013), the methane content found in biogas is considered adequate to be used in combustion and electric engine-generator sets. To Santana and Cohim (2010), the electric potential of biogas with 60% methane is 41.07 kw-m-3, what shows that electric energy production by means of biogas with these characteristics is feasible.

No contents of ammonia and sulphydric gas were detected in the biogas generated at the digester with whey, what demonstrates that this biogas is cleaner, therefore excluding the necessity of air purifier filters. This leads to reduction in handling costs, preservation of combustion quality and avoids bigger damages to the power generator.

Conclusion

The results of this study indicate that biogas production by anaerobic digestion of cheese whey using swine wastewater as inoculum is possible and feasible. In the treatment at 32ºC there was a reduction of 53.11% in volatile solids and biogas yield of 270 L (kg-sv-1) with 63% methane content. In the treatment at 26ºC, the reduction was 45.76% and the yield reached 171 L (kg-sv-1) with 61% methane content, what demonstrates the high energetic potential of biogas produced by cheese whey digestion.

References

Amon, T.; Amon, B.; Kryvoruchko, V.; Zollitsch, W.; Mayer, K. and Gruber, L. (2007) - Biogas production from maize and dairy cattle manure Influence of biomass composition on the methane yield. Agriculture, Ecosystems & Environment, vol. 118, n. 1-4, p. 173–182.

http://dx.doi.org/10.1016/j.agee.2006.05.007

Cáceres, G.X.; Cáceres, R.E.; Hein, D.; Molina, M.G. and Pia, J.M. (2012) - Biogas production from grape pomace?: thermodynamic model of the process and dynamic model of the power. International Journal of Hydrogen Energy, vol. 37, n. 13, p. 1011-1017. http://dx.doi.org/10.1016/j.ijhydene.2012.01.178 [ Links ]

Cheng, C. (2007) - Energia alternativa na indústria láctea?: a produção e aproveitamento de biogás numa pequena queijaria minhota. In: 2as Jornadas de Hidráulica: Recursos Hídricos e Ambiente, Porto, FEUP, p. 157–161. [ Links ]

Comino, E.; Riggio, V.A. and Rosso, M. (2012) - Biogas production by anaerobic co-digestion of cattle slurry and cheese whey. Bioresource Technology, vol. 114, p. 46–53. http://dx.doi.org/10.1016/j.biortech.2012.02.090 [ Links ]

Comino, E., Rosso, M. and Riggio, V. (2010) - Bioresource Technology Investigation of increasing organic loading rate in the co-digestion of energy crops and cow manure mix. Bioresource Technology, vol. 101, n. 9, p. 3013–3019. http://dx.doi.org/10.1016/j.biortech.2009.12.025 [ Links ]

Ergüder, T.H.; Tezel, U.; Gu, E. and Demirer, G.N. (2001) - Anaerobic biotransformation and methane generation potential of cheese whey in batch and UASB reactors, Waste Management, vol. 21, n. 7, p. 643–650. http://dx.doi.org/10.1016/S0956-053X(00)00114-8 [ Links ]

Frigon, J.; Breton, J.; Bruneau, T.; Moletta, R. and Guiot, S.R. (2009) - Bioresource Technology The treatment of cheese whey wastewater by sequential anaerobic and aerobic steps in a single digester at pilot scale. Bioresource Technology, vol. 100, n. 18, p. 4156–4163. http://dx.doi.org/10.1016/j.biortech.2009.03.07 [ Links ]

Gelegenis, J.; Georgakakis, D.; Angelidaki, I. and Mavris, V. (2007) - Optimization of biogas production by co-digesting whey with diluted poultry manure. Renewable Energy, vol. 32, p. 2147–2160. http://dx.doi.org/10.1016/j.renene.2006.11.015 [ Links ]

Hjort-Gregersen, K.; Blandford, D. and Gooch, C.A. (2011) - Biogas from Farm-based Biomass Sources. EuroChoices, vol. 10, n. 3, p. 18-23. http://dx.doi.org/10.1111/j.1746-692X.2011.00211.x [ Links ]

Janczukowicz, W.; Zielin, M. and Debowski, M. (2008) - Biodegradability evaluation of dairy effluents originated in selected sections of dairy production. Bioresource Technology, vol. 99, n. 10, p. 4199–4205. http://dx.doi.org/10.1016/j.biortech.2007.08.077 [ Links ]

Kavacik, B. and Topaloglu, B. (2010) - Biogas production from co-digestion of a mixture of cheese whey and dairy manure. Biomass and Bioenergy, vol. 34, n. 9, p. 1321–1329. http://dx.doi.org/10.1016/j.biombioe.2010.04.006 [ Links ]

Lehtomaki, A.; Huttunen, S. and Rintala, J.A. (2007) - Laboratory investigation on co-digestion of energy crops and crop residues with cow manure for methane production: effect of crop to manure ratio. Resources Conservation and Recycling, vol. 51, n. 3, p. 591–609. http://dx.doi.org/10.1016/j.resconrec.2006.11.004 [ Links ]

Maizonnasse, M.; Plante, J.; Oh, D. and Laflamme, C.B. (2013) - Investigation of the degradation of a low-cost untreated biogas engine using preheated biogas with phase separation for electric power generation. Renewable Energy, vol. 55, p. 501–513. http://dx.doi.org/10.1016/j.renene.2013.01.006 [ Links ]

Panesar, P.S.; Kennedy, J.F.; Gandhi, D.N. and Bunko, K. (2007). Bioutilisation of whey for lactic acid production. Food Chemistry, vol. 105, n. 1, p. 1–14. http://dx.doi.org/10.1016/j.foodchem.2007.03.035 [ Links ]

Prazeres, A.R., Carvalho, F. and Rivas, J. (2012) - Cheese whey management?: a review. Journal of Environmental Management, vol. 110, p. 48–68. http://dx.doi.org/10.1016/j.jenvman.2012.05.018 [ Links ]

Rojas, C.; Uhlenhut, F.; Schlaak, M. and Borchert, A. (2011) - Simulation des anaeroben Prozesses bei der Biogaserzeugung. Chemie Ingenieur Technik, vol. 83, n. 3, p. 306–321. http://dx.doi.org/10.1002/cite.201000100 [ Links ]

Santana, N. and Cohim, E. (2010) - Geração de energia elétrica a partir do biogás produzido na Estação de Tratamento de Esgotos de Madre de Deus – Bahia. Salvador Bahia, Faculdade de Tecnologia e Ciências. [ Links ]

Teghammar, A.; Forgács, G.; Sárvári, I. and Taherzadeh, M.J. (2014) - Techno-economic study of NMMO pretreatment and biogas production from forest residues. Applied Energy, vol. 116, p. 125–133. http://dx.doi.org/10.1016/j.apenergy.2013.11.053 [ Links ]

USDA (2014) - UNITED STATES DEPARTMENT OF AGRICULTURE. Homepage do USDA, 2014. [cited 2014.04.15]. Available at: http://www.fas.usda.gov/psdonline [ Links ]

Received/recebido: 2015.07.20

Accepted/aceite: 2015.12.16