INTRODUCTION

Peach quality, like other fresh fruits, can be related with global appearance, firmness, flavour, colour, aroma, nutritional value and food safety (Crisosto et al., 1996). The peach is appreciated for its excellent flavour and taste (Zhao et al., 2019; Zhou et al., 2019). Peach, as a climacteric fruit (Kader, 2002), presents an increase of respiration rate and ethylene production near maturation initiating in a very quick decay of peach firmness (Lurie & Crisosto, 2005; Ortiz et al., 2011; Li et al., 2014), resulting in a very perishable fruit at ambient temperature and a short storage life (Manganaris et al., 2007; Abidi et al., 2015). To extend commercial life, farmers tend to harvest fruits with higher firmness which can compromise quality as in postharvest the refrigeration method is overspread. Peach fruit quality can be seriously affected by storage process, especially when peaches are maintained in a low-temperature storage range, appearing symptoms as dry texture, taunting floury pulp and flavour loss, known as chilling injury (CI) (Manganaris et al., 2006; Abbasi et al., 2019; Liu et al., 2019; Nilo-Poyanco et al., 2019; Zhao et al., 2019). According to Lurie and Crisosto (2005) and Crisosto et al. (1999) CI is a physiological disorder and develops when the storage conditions are between 2.2 °C and 7.6 °C, named as killing temperature zone.

Beira Interior region is the main peach producer in Portugal. Peach farmers, that manage areas of 20 ha to 50 ha (Dias et al., 2016), mainly have refrigeration chambers to storage and extend shelf life of peaches. The storage process is characterized as the higher energy consume in the peach produce process (Gaspar et al., 2018), and fruit industry is the higher energy consumer compared to the other agrifood industries (Silva et al., 2014). However, the management of refrigeration chambers is very different between farmers, which will be reflected in peach quality and its shelf life.

As peach cultivars have a short period of exploitation because life cycle of peach tree is short (12 to 14 years) (Simões, 2016), and new peach cultivars are always coming every year, there is a frequent renovation of peach orchards (Simões, 2008), but there is not a precise knowledge about different cultivar postharvest behaviour.

This study aims to contribute to the characterization of postharvest storage conditions used to extend peach shelf life of two different cultivars - ‘Royal Time’ and ‘Royal Summer’ at three different producers. As peach cultivars have very distinct acidity content, influence of storage conditions in peach quality loss will be highlighted.

MATERIALS AND METHODS

To this study we used 3 refrigeration conditions using farmer’s refrigeration chambers (local C, local G e local L), 2 different cultivars - Royal Time (RT) and Royal Summer (RS) - harvested in the beginning of July and 6 sampling times (t0, t7, t14. t21, t28, t35). The sampling was performed weekly during the 35 days of the study.

At harvest time, fruits were selected from the deliver container based on size and colour, to have the most homogeneous fruits, without imperfections. At laboratory, 30 boxes of 24 fruits each were prepared, corresponding each box to each refrigeration chamber and time and cultivar. Each fruit was marked individually and weight and colour were evaluated as described below. After this characterization, fruits were transported to farmer’s refrigeration chambers with a datalogger (EL-USB-2, Lascar) inside the lowest box to have a continuous monitorization of air temperature and air relative humidity with an accuracy of 0.3 °C and 2.3 %, respectively. Each 7 days, a box of each cultivar and refrigeration chamber was picked and fruits were analysed at IPCB-ESA laboratory, proceeding to evaluation of the presence of rotten fruits, the weight and colour in 2 points/fruit (using colorimeter Minolta model CR-and CIE system L* a* b*, based on the 24 fruits. After, for destructive parameters we use only half of the sample (12 fruits), evaluating firmness, using a PENEFEL device with 8 mm diameter point, total soluble solids (TSS) expressed as %, using digital Atago refractometer using some drops of juice extracted from the holes of PENEFEL use, and titratable acidity, expressed as g malic acid/L, obtained by potentiometric titration to pH 8.3 by a 0.1M NaOH solution.

The evaluation of rotten fruits was performed by direct observation and expressed as a percentage of fruit. The rotten fruits were only discarded for subsequent analysis if the rotten area was extensive and compromises the others determinations. The sample that remained at room temperature didn’t present any rotten fruit at ti time.

The chilling injury evaluation, expressed as a percentage of affected fruits, was performed on 12 fruits after 2 days at room temperature (22 to 25 ºC) by the observation of the fruit pulp after cutting it in 2 halves through the lengthwise direction. If the pulp showed a brown colour and/or a woolly texture, the fruit was considered to be chill injured (Crisosto et al., 1996).

Statistical analysis was performed using SPSS 24 (IBM, 2016). Data assumptions of variance normality and homogeneity were verified using, respectively, the Kolmogorov-Smirnov test and the Levene Statistic (Maroco, 2011). Despite data normal distribution was not observed, sample was large enough to allow the use of a parametric test (Maroco, 2011).

One-Way ANOVA analysis was used to find significant statistical differences between time, for all modalities. After analysis, Scheffé test was applied for multiple comparisons.

RESULTS AND DISCUSSION

Refrigeration chamber temperature and humidity conditions

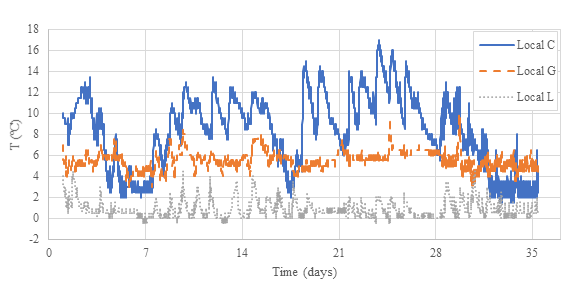

Temperature conditions, in the three refrigeration chambers, through the trial period can be observed in Figure 1. The results show very distinct conditions. At local C air temperature shows a high oscillation (σ=3.53 °C) with a mean value of 8.29 °C and a maximum thermal amplitude of 15.5 °C. At local G air temperature shows more stability (σ=0.88 °C) with an average temperature of 5.5 °C and a maximum thermal amplitude of 7 °C. Local L shows the best temperature stability of the air temperature (σ=0.83 °C) with an average value of 0.80 °C and maximum thermal amplitude of 5 °C (Table 1).

Air relative humidity of storage conditions for the 3 farmers were similar, corresponding to 95.5%±5.0% for local C, 89.9%±4.6% for local G and 98.1%±3.5% for local L, close to the range of 90% - 95% recommended by Crisosto et al. (1996) (Table 1).

Characteristics of Royal Summer (RS) and Royal Time (RT) cultivars

In this study we used two distinct cultivars with similar harvest time (Ferreira et al., 2017). Although slight differences between cultivars were observed (in weight, firmness and TSS), the main distinctive quality parameter is acidity content. Royal Summer had lower acidity (3.63 malic ac. g/L) than RT (8.45 malic ac. g/L) (Table 2). Quality parameters of peaches at t0 (harvest time) are shown at Table 2. RS has slight heavier fruits (193 g/fruit) corresponding to A class fruits (155 g/fruit - 195 g/fruit, according to Simões and Ferreira (2015)), a firmness of 6.61 kgf, that is higher than average referred by Ferreira et al. (2017), for peaches of middle season, namely 5.1±1.4 kgf at 2015 and 4.8±1.3 kgf at 2016, and a TSS of 13.6 ºBrix, similar of referred by Ferreira et al. (2017). Peaches of RT cultivar were 182 g/fruit, also class A, a firmness of 5.2 kgf and 11,23 ºBrix. Although there were observed significate differences respecting to fruit weight, fruits of both cultivars belong to the same size classification. Respected to colour parameters (L*a*b*), no significate differences were observed between cultivars at harvest time (Table 2).

Table 2 Quality of Royal Summer and Royal Time at harvest time (t0)

| Royal Summer | Royal Time | p | ||||

| w (g) | 193.67 | a | 182.54 | b | 0.025 | |

| L* | 40.17 | a | 43.37 | a | 0.082 | |

| a* | 22.97 | a | 25.63 | a | 0.105 | |

| b* | 13.97 | a | 15.10 | a | 0.556 | |

| c* | 27.95 | a | 30.08 | a | 0.183 | |

| h* | 0.49 | a | 0.50 | a | 0.880 | |

| Firmness (kgf) | 6.61 | a | 5.20 | b | 0.000 | |

| TSS (ºBrix) | 13.60 | a | 11.23 | b | 0.000 | |

| Acidity (malic ac g/L) | 3.63 | b | 8.45 | a | 0.000 | |

Different letters in the same line correspond to significant differences between values. (n=360)

At harvest, cv. Royal Summer has 6.61 kgf of firmness which is in the interval of firmness of 6 and 8 kgf usually used by farmers (Santos, 2019) and is very interesting for fruit life postharvest. When fruit acidity is lower, farmers can harvest earlier because consumer acceptance is not negatively affected. Crisosto and Crisosto (2005) referred that consumers prefer cultivars of low acidity content, and peach high acidity content doesn’t allow the perception of high TSS content.

At harvest, Royal Time firmness was 5.2 kgf, very similar to 5.1 kgf reported by Ferreira et al. (2017) and Rodrigues (2018) that work also with RT cultivar. Data from local trials (not published) show that when Royal Time has been harvested at 5.4 kgf firmness the acidity content was >10 malic ac. g/L.

Effect of storage conditions on fruit firmness

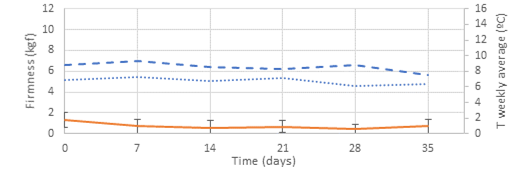

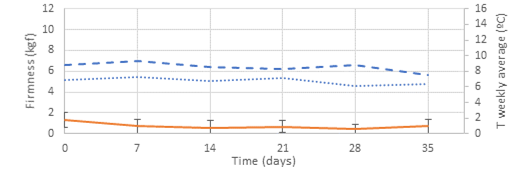

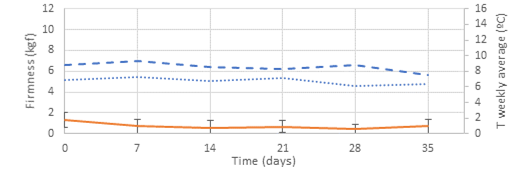

Firmness is one of the most important quality parameters for peaches because it affects appearance and manipulation during postharvest process and commercial chain (Crisosto, 1994). Refrigeration is the process used to delay softening and slow down respiration and maturation process. Firmness evolution and decay along storage period, for the two cultivars, is shown in Figure 2 (local C, local G and local L). Figure also shows the weekly average air temperatures in refrigeration chambers.

Figure 2 Peach firmness evolution, for cultivar Royal Summer (dashed line, - - -) and Royal Time (dotted line, ……) related to average weekly temperature (full line) at local C, local G and local L during conservation period.

At local C, weekly average air temperature was in the range 5°C to 9 °C, which is much higher than -0,5ºC to 1ºC indicated by Girardi et al. (2005), Ceretta et al. (2000) and, as expected, peach firmness decreases quickly. At 14 days, firmness is 3 kgf for RS and bellow 2 kgf for RT, which are near the values of ready to eat (1 kgf) according to Crisosto et al. (1996), but are inappropriate for postharvest processing at warehouse. Temperature conditions in local C are inappropriate for peach storage and for extending shelf life period.

At local G, weekly average temperature was between 5 °C and 7 °C, just inside the range of 2.2 °C to 7.6 °C considered killing temperatures because of its high correlation with chilling injury incidence (Crisosto et al., 1996; Crisosto et al., 2002; Lurie & Crisosto, 2005; Rodrigues et al., 2020a). Different behaviour of peach firmness was observed between RS and RT cultivars. Fruits from RS cultivar maintain firmness around 6 kgf during 14 days and decrease to 4 kgf at 21 days. For RT cultivar fruit firmness decrease regularly from harvest (t0), reaching 4 kgf before 14 days. By the end of storage, in local G, firmness differences are less evident between cultivars.

At local L, characterized by weekly average air temperature between 0 °C and 2 °C, fruit firmness is maintained near the harvest values for 35 days, with similar behaviour for both cultivars.

For storage conditions of local C and G, we observed a faster decay of firmness of Royal Time on the initial period, which is a negative characteristic of RT compared to RS.

Considering that the farmers at Beira Interior region usually use refrigeration for a short time of storage due to high diversity of cultivars and short distance of commercialization, the conditions of local G can be looked with high interest in terms of low energy consumption, a desirable international goal for sustainable food production (FAO, 2011), if other quality parameters would not be negatively affected. Costs with refrigeration chambers at warehouse are the most important fraction of energy consumption in life cycle of peach production (Gaspar et al., 2018), representing 2/3 of total energy consumption in MJ/t of peach. Taking only into account fruit firmness, a storage temperature between 0 °C and 2 °C will represent an additional cost for producers if peaches will stay only for a period of 7 days. On the other way, Liu et al. (2015) refers that for short conservation period the range of 4 to 6 °C is favourable for obtaining higher content of antioxidants. Although the interest of this range of storage temperature represents in terms of shortening costs, the farmers must be aware of the risk if the fruits must remain for a longer period, especially for RT cultivar. Results of Rodrigues (2018), working with RT cultivar show that Chilling Injury was only present after 21 days of storage, for a range of storage temperature of 4 ºC to 10 ºC.

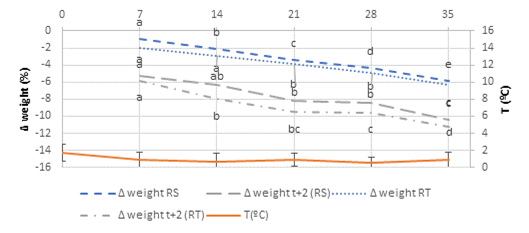

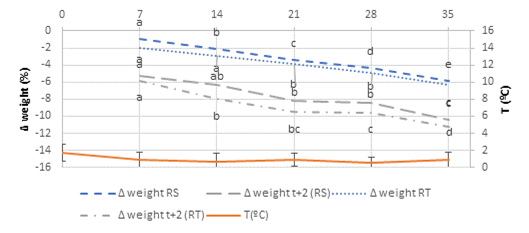

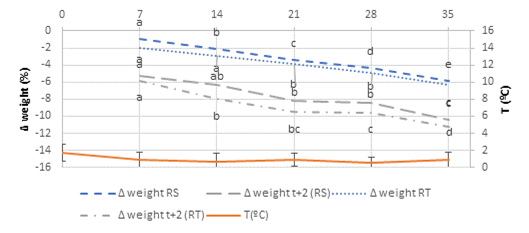

Effect of storage conditions on weight fruit loss

After harvest fruit continues its process of respiration which results in weight loss, pectin and acid degradation (Crisosto et al., 1996; Du et al., 2017). Weight losses leads to money loss and sometimes a point of conflicts and complains in the commercial chain. Figure 3 (local C, local G and local L) presents the fruit weight losses at different sampling dates. Evaluations were done just after storage exit and after 2 days at room temperature (22 ºC - 25 ºC, for warm summer of this region of Beira Interior).

In terms of weight losses RS and RT behave differently. RS show, in all conditions, less weight losses compared to RT. This may be due to a lower respiration rate related with its higher firmness, an indicator of maturation.

Considering t7 of storage weight losses of RS was in average 2%/week for local C, 1,7%/week for local G and 1%/week for local L, observing a constant and linear decrease of fruit weight until t28, which reflects a clear effect of storage temperature on weight loss. For RT cultivar and t7, weight loss was in average 6%/week for local C and G, and 5%/week for local L. Considering the short storage period of 7 days, RS cultivar clearly advantageous in terms of less weight loss.

For local C, and t35, RS reached 7% of weight loss and there are significate differences in weight losses between all the times of storage. After 2 days at room temperature RS presents a decrease of 1% of weight compared to the storage exit day for t7, t14 and t21, but no additional weight loss for t28 and t35. For the same conditions of local C, RT cultivar presents 6% of weight loss for t7 and 10% for t21 and, for a storage period longer than 21 days, a high percentage of rotten fruits was observed (Table 3) which is impeditive of further quality analysis.

At local G and RS cultivar weight loss until t28 presents a linear behaviour, corresponding to an average of 0.22%/day compared to an average of 0.28%/day for RT. During the last week (t28 to t35) the weight loss presents a higher decrease of 5% for RS and 6% for RT, probably corresponding to a senescence period. Considering ti+2, (t7 to t21), after 2 days at room temperature, RS presents 1% of weight loss (compared to ti) and RT presents 2% of weight loss. The last week results indicate that fruits are senescent and the conservation conditions are inappropriate for such a long period.

At local L, characterized by storage temperatures between 0 and 2 °C, loss of weight for RS and t14 was 2% and can be observed a 0.14%/day of weight loss until t28 with a linear decrease of weight loss. Significate differences are observed between all times of storage. Comparatively, for the same t14, RT presents 6% of weight loss and reached 10% of weight loss for t28. After 2 days at room temperature (ti+2), and for the period of t7 to t21, RS cultivar presents 1% of decrease compared to ti time of storage. Comparatively RT cultivar presents 1,5% to 2% of weight loss after the period at room temperature (Figure 3, local L).

Figure 3 Percentage of weight loss over time for Royal Summer (dashed - - - and dotted …… lines) and Royal Time (long dashed -- -- -- and dash-dotted -.-.- lines) cultivars just after refrigeration period (dashed - - - and -- -- -- lines) and after 2 days at room temperature (dotted …. and dash-dotted -.-.- lines), related with different temperature conditions (full line) at local C, local G, and local L. Different letters correspond to significant differences through the time period (p<0.05).

Effect of refrigeration conditions on rotten fruits and chilling injury

Percentage of rotten fruits and chilling injury (CI) for each local, time of storage and cultivar are presented in Table 3.

The results suggest that storage conditions of local C and G are not appropriated for fruit quality maintenance for t>7. For local C, the RT cultivar 25% of fruits were rotten at t7+2, making them not suitable for trade intervenient or consumers.

Local L allows a longer period of storage. Fruits stored until 14 days showed the quality required at consumer level. At time t21+2, 25% of rotten fruits were observed for RT and 8% for RS.

The higher percentage of CI was observed for local L at t35. At local C and G the rotten fruits incidence overcome the problem of CI, which indicate that a proper use of fungicides near harvest is highly recommended to avoid this problem as suggested by Nanos and Mitchell (2019).

CI first appeared in Local G at t21+2 and an incidence of 33.3% was observed (Table 3). Rodrigues et al. (2020b), in a similar study, also found the first CI symptoms after t21+2.

Table 3 Percentage of rotten fruits and Chilling Injury for Royal Summer and Royal Time at different locals of refrigeration

| t (days) | Local C | Local G | Local L | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RS | RT | RS | RT | RS | RT | ||||||||

| t | t+2 d | t | t+2 d | t | t+2 d | t | t+2 d | t | t+2 d | t | t+2 d | ||

| Rotten | 7 | 25.0% | |||||||||||

| 14 | 4.2% | 16.7% | 8.3% | 36.4% | 25.0% | 33.3% | |||||||

| 21 | 4.2% | 58.3% | 25.0% | 22.2% | 16.7% | 50.0% | 8.3% | 25.0% | |||||

| 28 | 41.7% | 83.3% | 41.7% | 71.4% | 25.0% | 12.5% | 58.3% | 16.7% | |||||

| 35 | 66.7% | 100.0% | 58.3% | 100.0% | 29.2% | 33.3% | 41.7% | 25.0% | 8.3% | 4.2% | 16.7% | ||

| Chilling injury | 7 | ||||||||||||

| 14 | |||||||||||||

| 21 | 33.3% | ||||||||||||

| 28 | 33.3% | 8.3% | 16.7% | 25.0% | 41.7% | ||||||||

| 35 | 14.3% | 4.2% | 83.3% | 75.0% | |||||||||

Note: Percentage of rotten fruits correspond to the 24 fruits of each sample for t time and ≤12 fruits for t+2. All the rotten fruits were discarded at ti time.

Conclusions

The main goal of this study was to monitor the storage conditions used by Portuguese peach local farmers in the Beira Interior region to preserve postharvest fruit quality and to extend fruit ability to market and consumer acceptance, comparing to different cultivars that have the same harvest period and, because of it they area alternative one to each other. Results suggest that farmers mainly use inadequate temperatures for long storage periods. However, if farmers need to store peaches from 7 days, conditions near those of local G allow fruits to maintain good quality without lacking of ripening or problems of chilling injury, and, simultaneously, save energy which is also a desirable goal (FAO, 2011). ‘Royal Summer’, comparatively to ‘Royal Time’, allow an earlier harvest resulting in higher firmness at harvest time and firmness maintenance for longer period and less weight loss during conservation.

For longer commercialization periods (such faraway international markets), optimum conservation conditions (0-2 °C) should be applied by farmers in order to extend the peach commercial value and avoid losses and Summer Time cultivar presents better postharvest quality behaviour.